PRODUCTS

Contact us

86 17344894490Mobile:86 17344894490

Email:info@signialuminium.com

Skype:signialuminio

Sales Office:A126 Building 4, No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan,China

Factory Address:Industrial District, Xin'an, Luoyang city, Henan Province,China

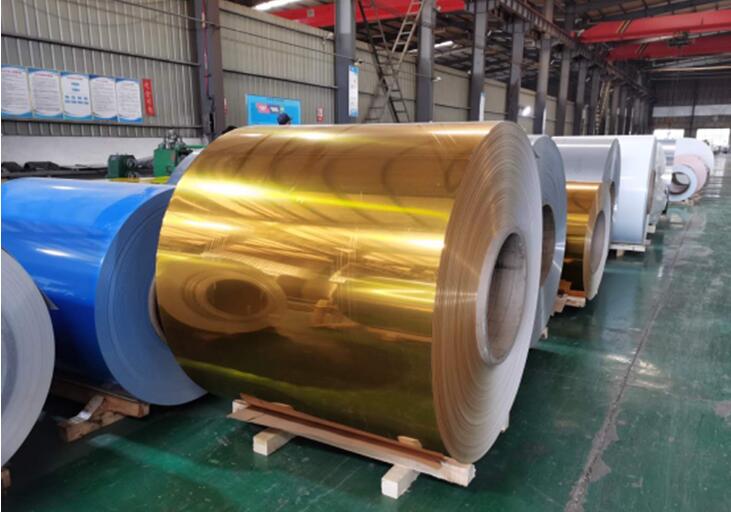

high polished aluminum sheet

high polished aluminum sheet

The high polished aluminum sheet is processed by precision grinding, and the surface is not electroplated. Before sandblasting and anodizing, there is no need to remove the anode or electroplating film, and it can be directly sandblasted. Anode processing, sandblasting roughness can reach 320# or more. Generally divided into mechanical polishing, chemical polishing and electrolytic polishing.

Mirror aluminum mechanical polishing: Imported mirror aluminum mechanical polishing is a polishing method that relies on cutting and plastic deformation of the material surface to remove the polished convexities to obtain a smooth surface. Generally, oil stone strips, wool wheels, sandpaper, etc. are used, mainly by manual operation. For special parts such as the surface of a rotating body, auxiliary tools such as turntables can be used, and ultra-precision polishing can be used for high surface quality requirements. Ultra-precision polishing is the use of special abrasive tools, which are pressed against the processed surface of the workpiece in a polishing fluid containing abrasives for high-speed rotation. The surface roughness of Ra0.008μm can be achieved by using this technology, which is the highest among various polishing methods. Optical lens molds often use this method. Mirror surface aluminum chemical polishing: Imported mirror surface aluminum chemical polishing is to make the surface microscopic convex part of the material in the chemical medium dissolve preferentially than the concave part, thereby obtaining a smooth surface. The main advantage of this method is that it does not require complicated equipment, it can polish workpieces with complex shapes, and it can polish many workpieces at the same time, with high efficiency. The core problem of chemical polishing is the preparation of polishing liquid. The surface roughness obtained by chemical polishing is generally several 10 μm.

Mirror aluminum electrolytic polishing: The basic principle of imported mirror aluminum electrolytic polishing is the same as that of chemical polishing, that is, by selectively dissolving the tiny protrusions on the surface of the material to make the surface smooth. Compared with chemical polishing, it can eliminate the influence of cathode reaction, and the effect is better.

The high polished aluminum sheet has uniform hardness, which is suitable for complex stamping, bending, stretching, and shaping without breaking easily.

Surface treatment characteristics of high polished aluminum sheet: pure material, suitable for high-demand stable anodized surface treatment, such as chemical polishing, atomization bite mist, two-color secondary anode, sandblasting, chemical sanding, dyeing, sealing and other processing. Application of high polished aluminum sheet: ◎Electronic product shell: ◎Decoration: lighting decoration, interior decoration, exterior wall decoration, automobile interior decoration, household appliances decoration, etc.; ◎Others: signs, nameplates, luggage, jewelry boxes, etc.