PRODUCTS

Contact us

86 17344894490Mobile:86 17344894490

Email:info@signialuminium.com

Skype:signialuminio

Sales Office:A126 Building 4, No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan,China

Factory Address:Industrial District, Xin'an, Luoyang city, Henan Province,China

aluminium reflector for lighting

aluminium reflector for lighting

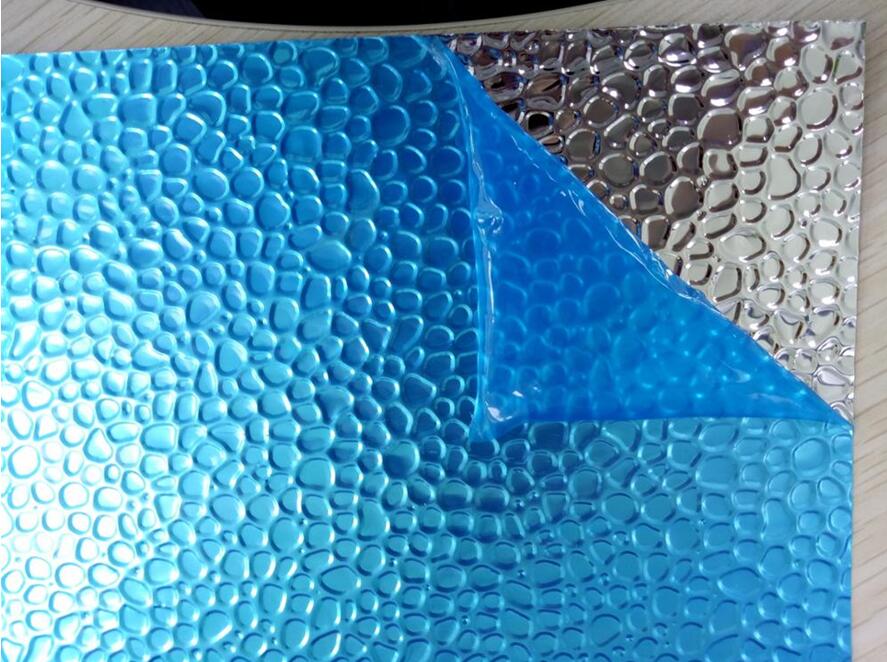

Mirror aluminum plate refers to the aluminum plate which is processed by rolling, grinding and other methods to make the surface of the plate present mirror effect. General mirror aluminum plate is rolled to produce coil and sheet. In the market, the application of plate is more common. In daily life, mirror aluminum plate is mainly used in lighting reflector and lamp decoration, solar collector reflective material, interior building decoration, exterior wall decoration, household appliance panel, electronic product shell, furniture kitchen, automobile interior and exterior decoration, sign, logo, luggage, headdress box and other fields.

1、 Application of aluminum reflector for lighting

1. Aluminum plate as incandescent lamp and fluorescent lamp holder, and other aluminum sheet material as socket has become a conventional use.

2. Cast, pressed and spun aluminum parts are often used as artistic decorations for table lamps, standing lamps and other lamps.

3. It is common for aluminum mirrors to be used in fluorescent lamp systems and other light installation systems.

4. In recent years, solar energy-saving lamps have been widely used, and aluminum alloy profiles or pipes have been used for the hood, socket, bracket connecting rod, etc.

2、 Features of aluminum reflector for lighting

1. Aluminum plate can reduce the light load. For example, 80 spotlights should be hung on a lamp post in an open-air sports ground, and the light aluminum lamp shows its advantages.

2. The service life of outdoor lamps is required to be more than 10 years, and the aluminum alloy lampshade with good corrosion resistance can meet this requirement. After anodizing, their surface not only improves the hardness and wear resistance, but also can be frequently scrubbed and decorated.

3. In order to reduce weight and save energy, transportation vehicles also use aluminum wires, aluminum coils and aluminum electrical parts. At present, aluminum alloy with good flexibility and creep resistance and effective low voltage (12V) electric contact material have been developed.